- Jiahe Liao is a postdoctoral researcher in the Soft Machines Lab with Prof. Carmel Majidi at Carnegie Mellon University. His research focuses on active soft materials that leverage the physics of liquids, particularly liquid metals, to unlock advanced material architectures and mechanisms that mimic biological functions in robots.

- Liao received his Ph.D. in robotics from Carnegie Mellon University in 2022 and completed a postdoctoral fellowship at the Max Planck Institute for Intelligent Systems in Germany from 2022 to 2024. Originally from Taiwan, his foundational research on soft actuators advances the fields of soft robotics, soft condensed matter physics, and bioinspired materials for next-generation robots.

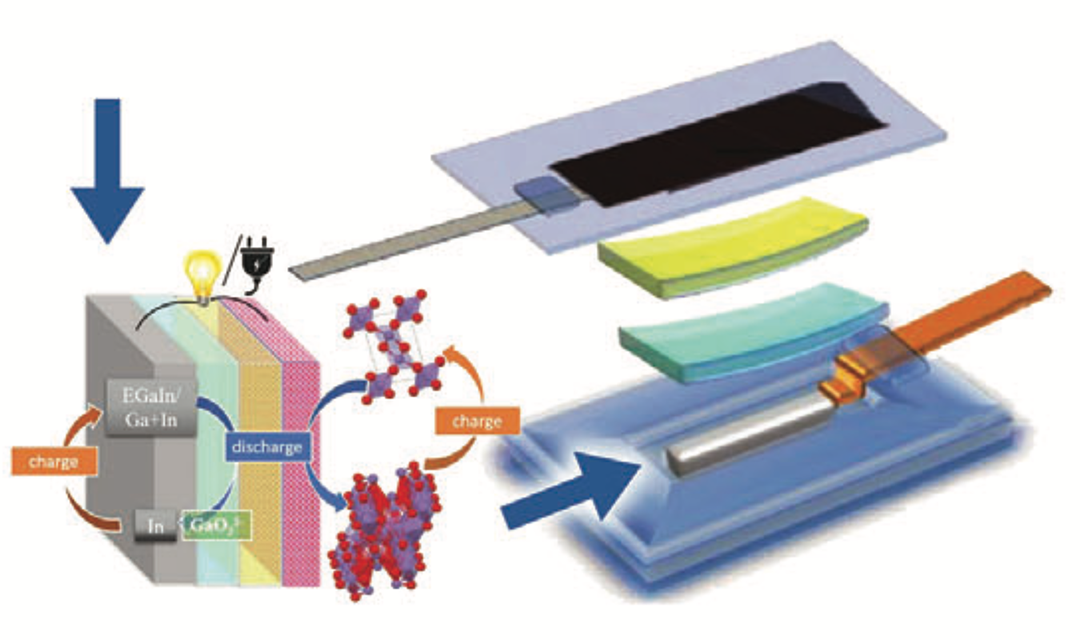

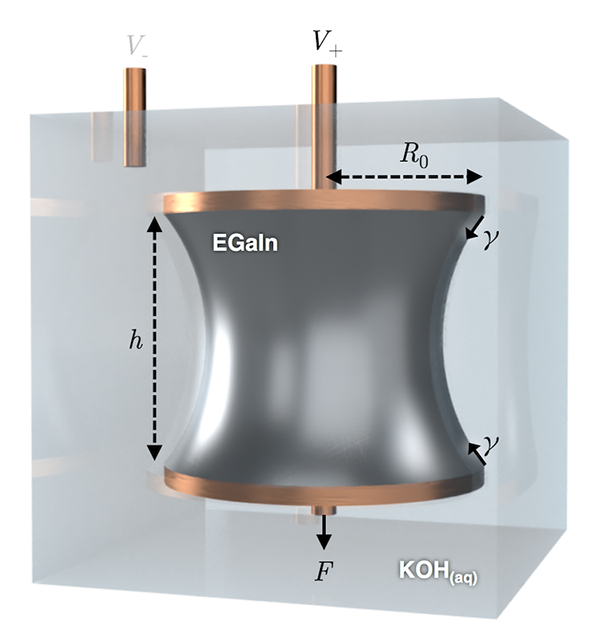

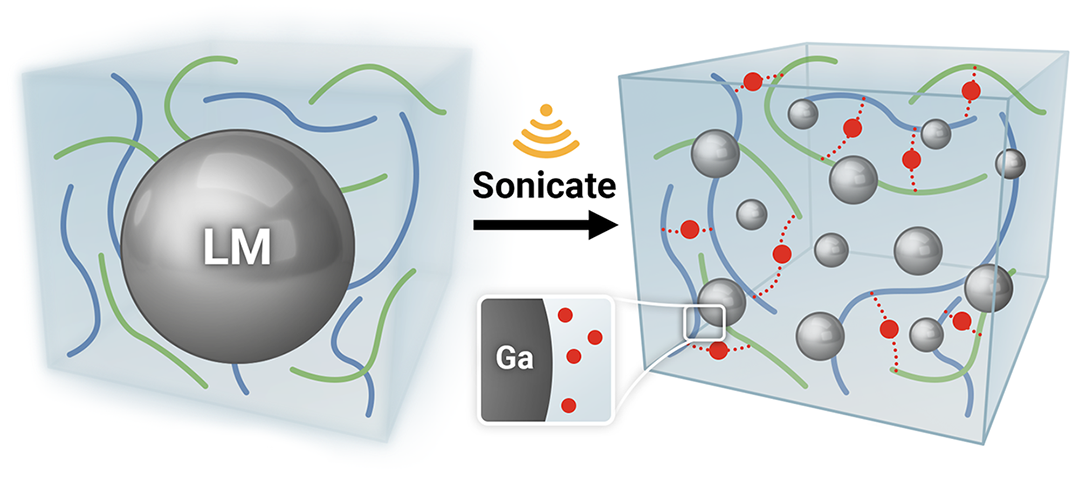

Liao et al. In Preparation. /

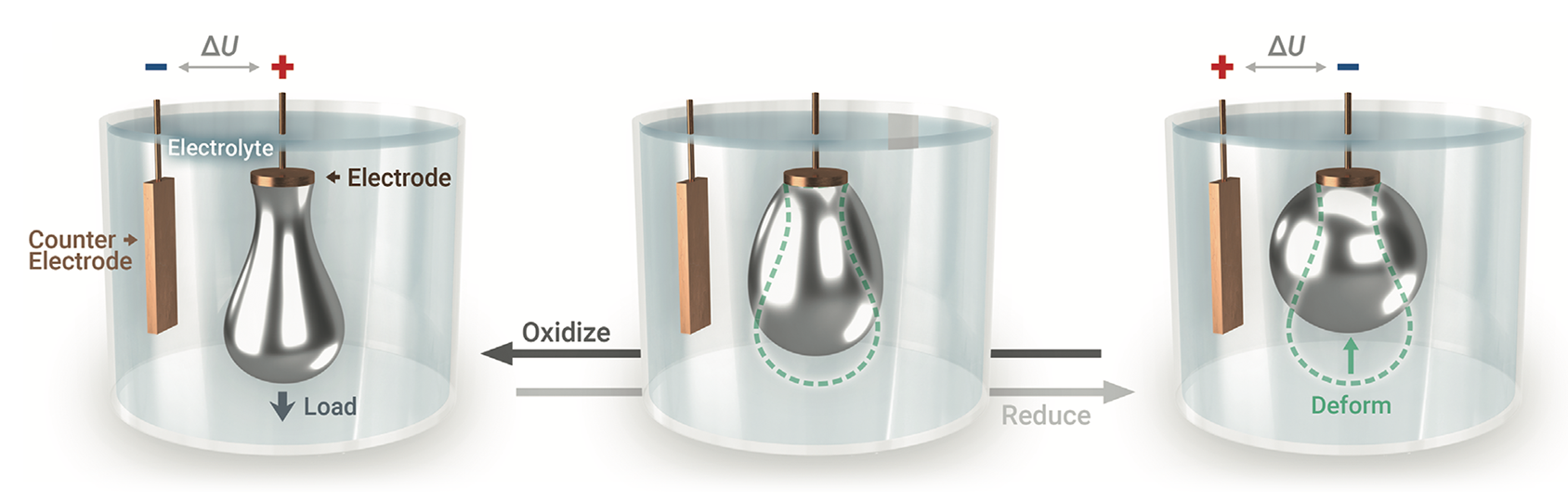

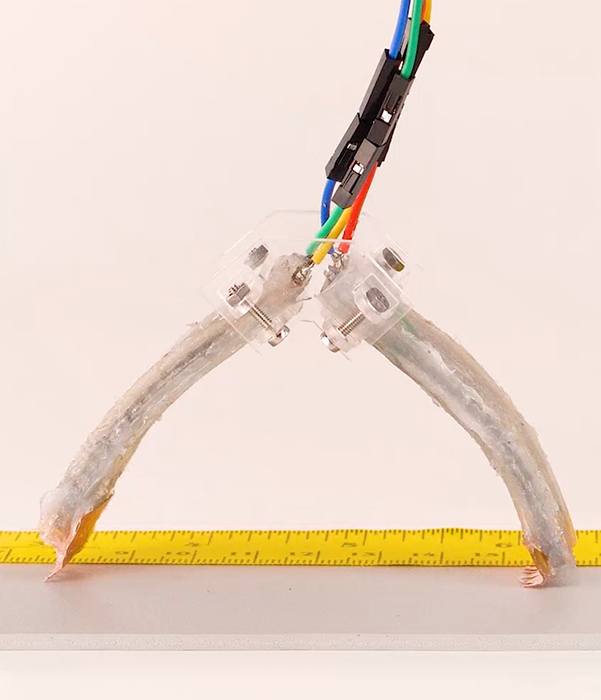

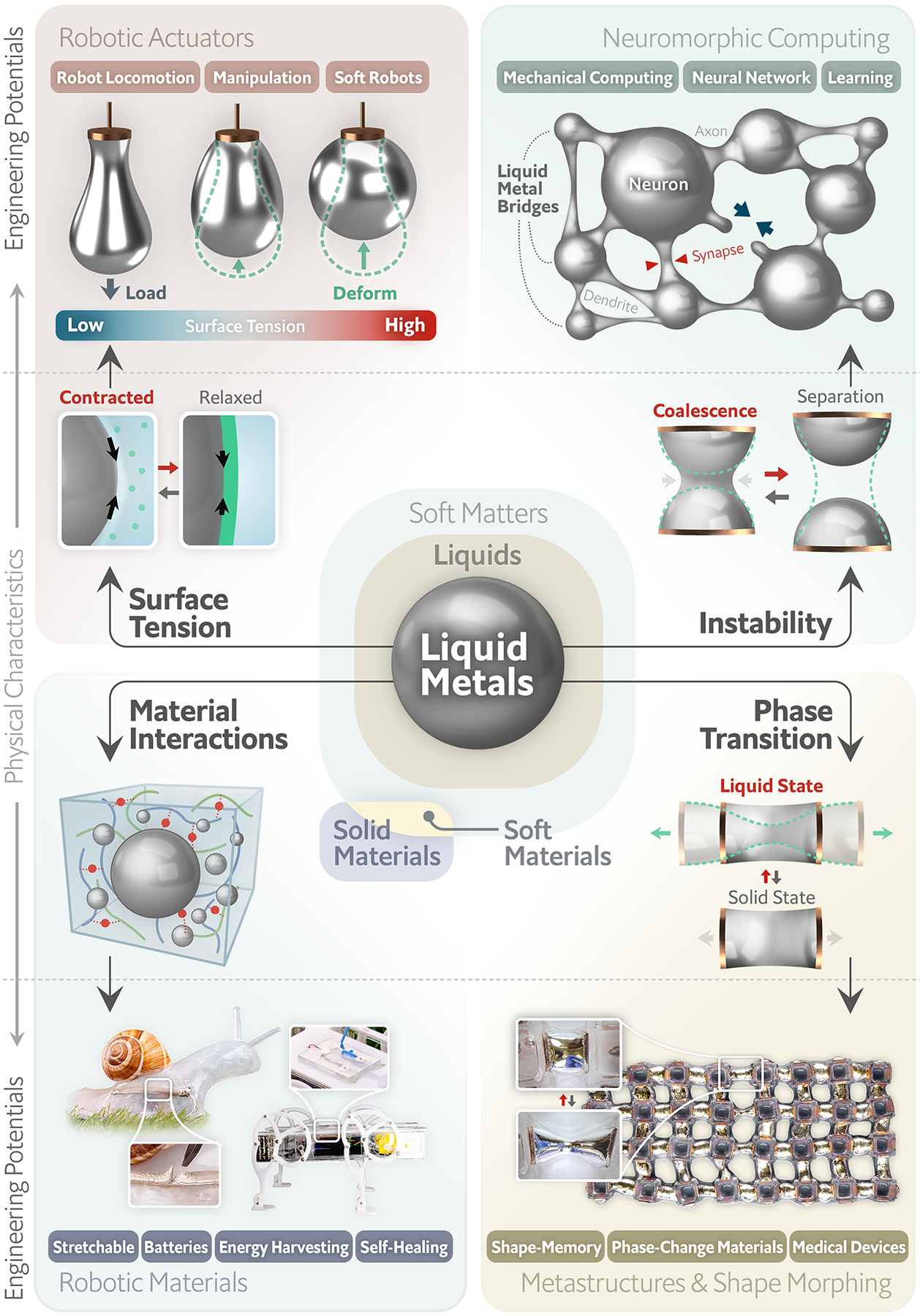

Liao et al., Advanced Science (2022) /

Liao et al. Carnegie Mellon PhD Thesis (2022) /

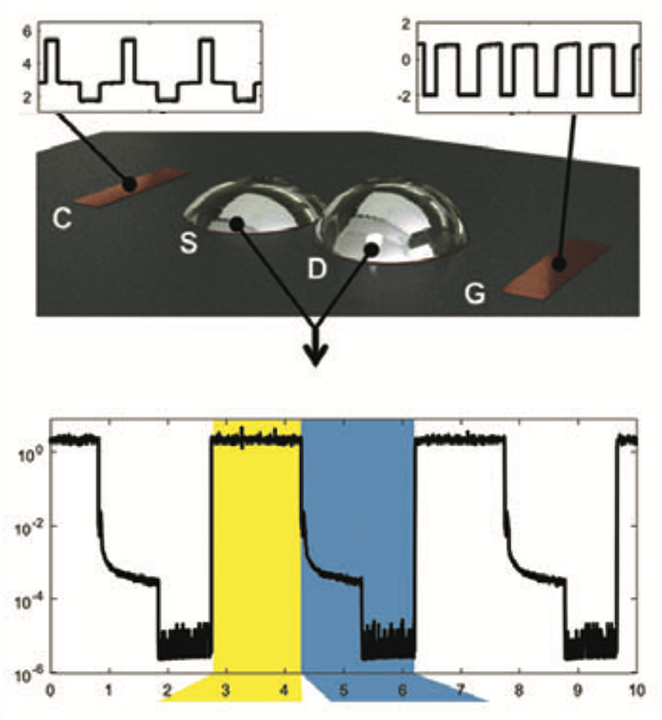

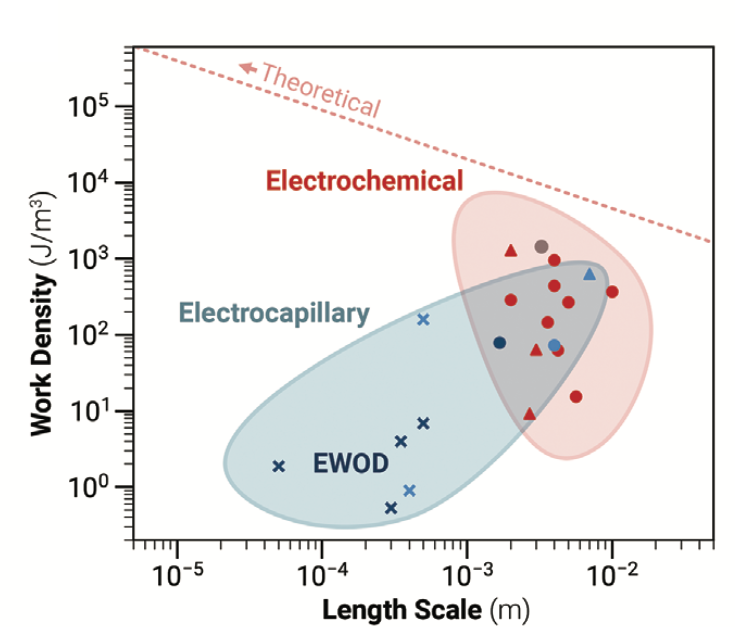

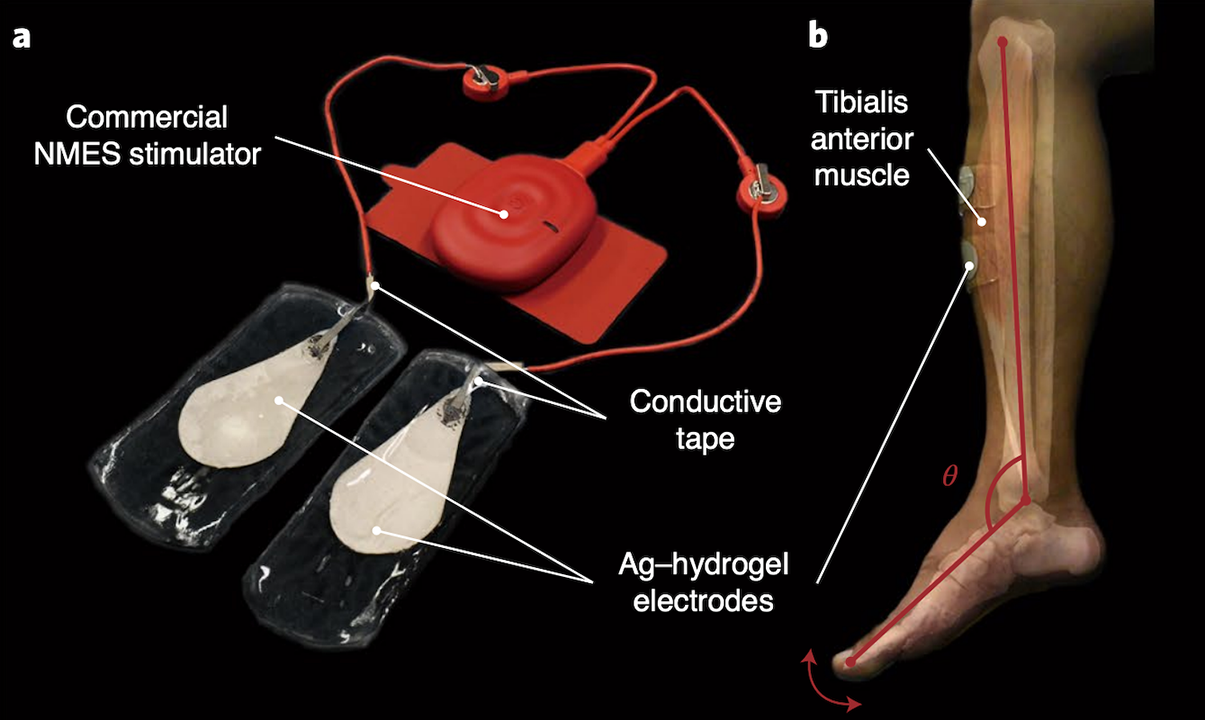

Zhao et al., Nat. Electron. (2023) /

Zhang and Liao et al., Adv. Funct. Mater. (2023).

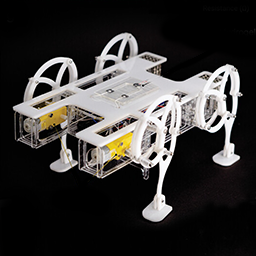

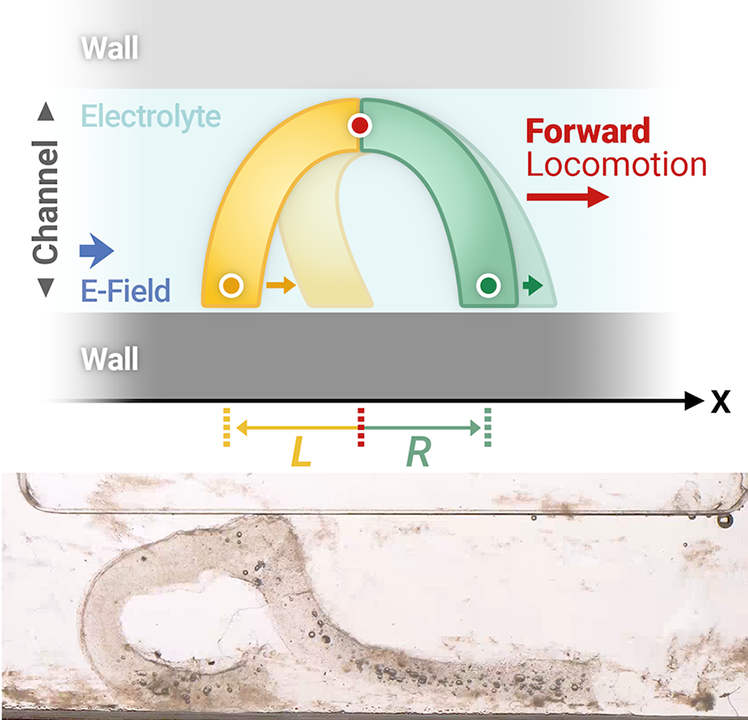

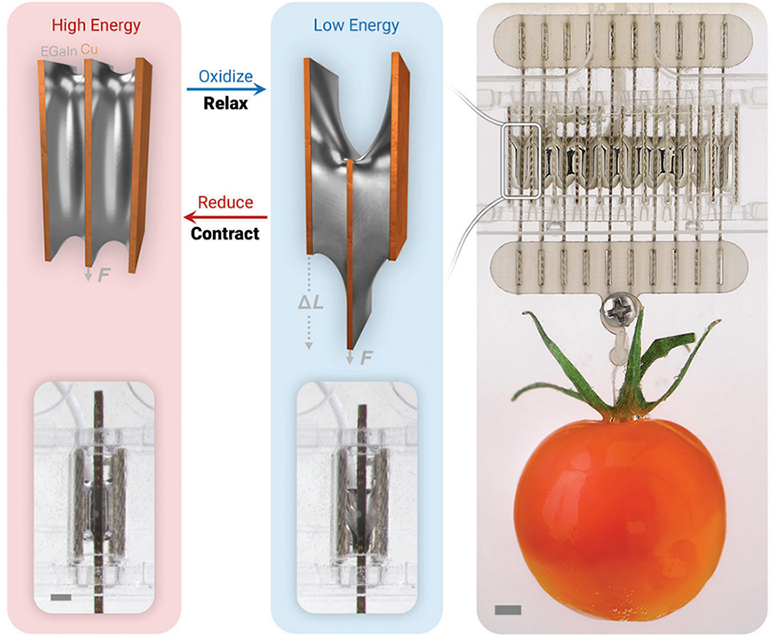

Liao et al. In Preparation. /

Liao et al., Advanced Science (2022)

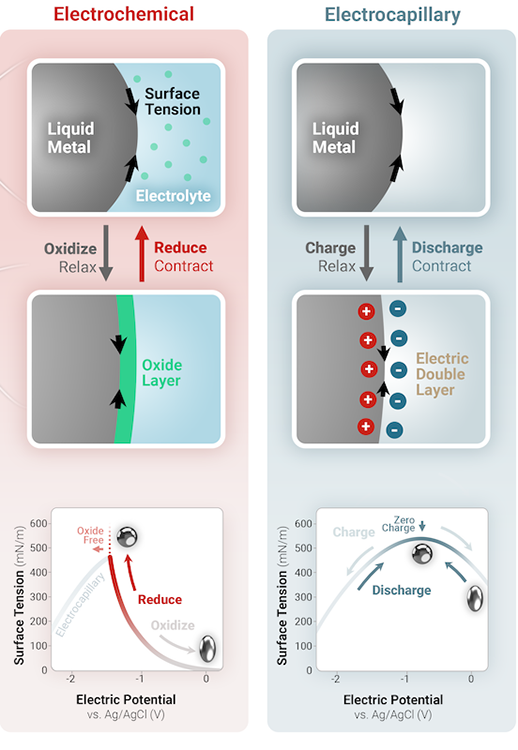

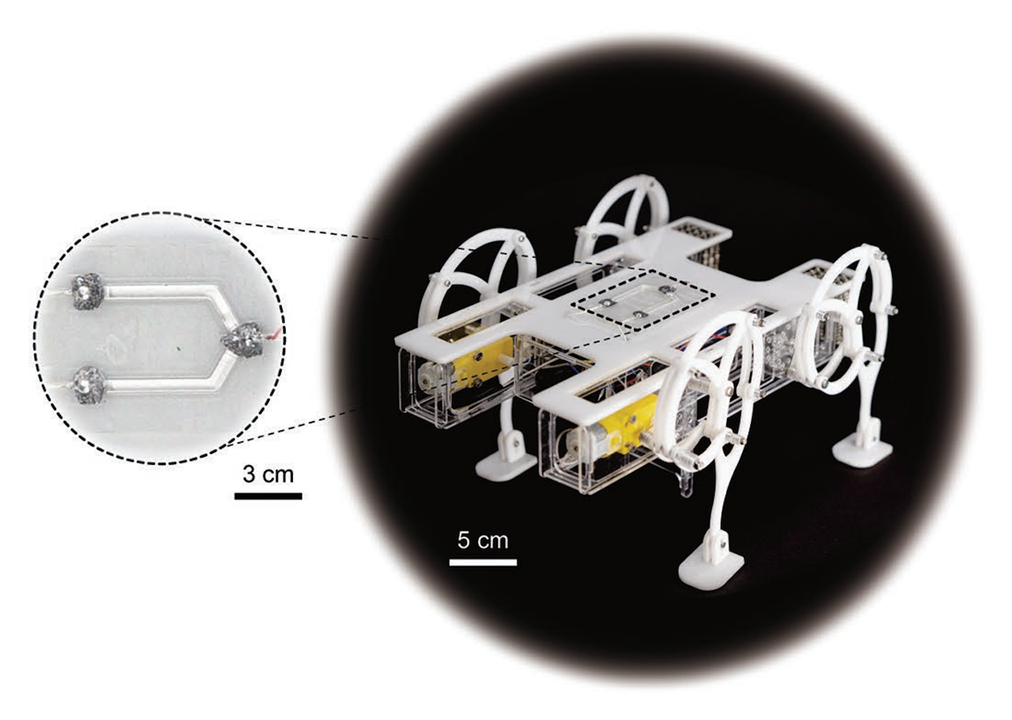

Zadan et al., Adv Mater. (2021) /

Zhao et al., Nat. Electron. (2023) /

Ohm et al., Adv. Mater. (2023)

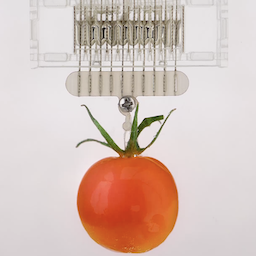

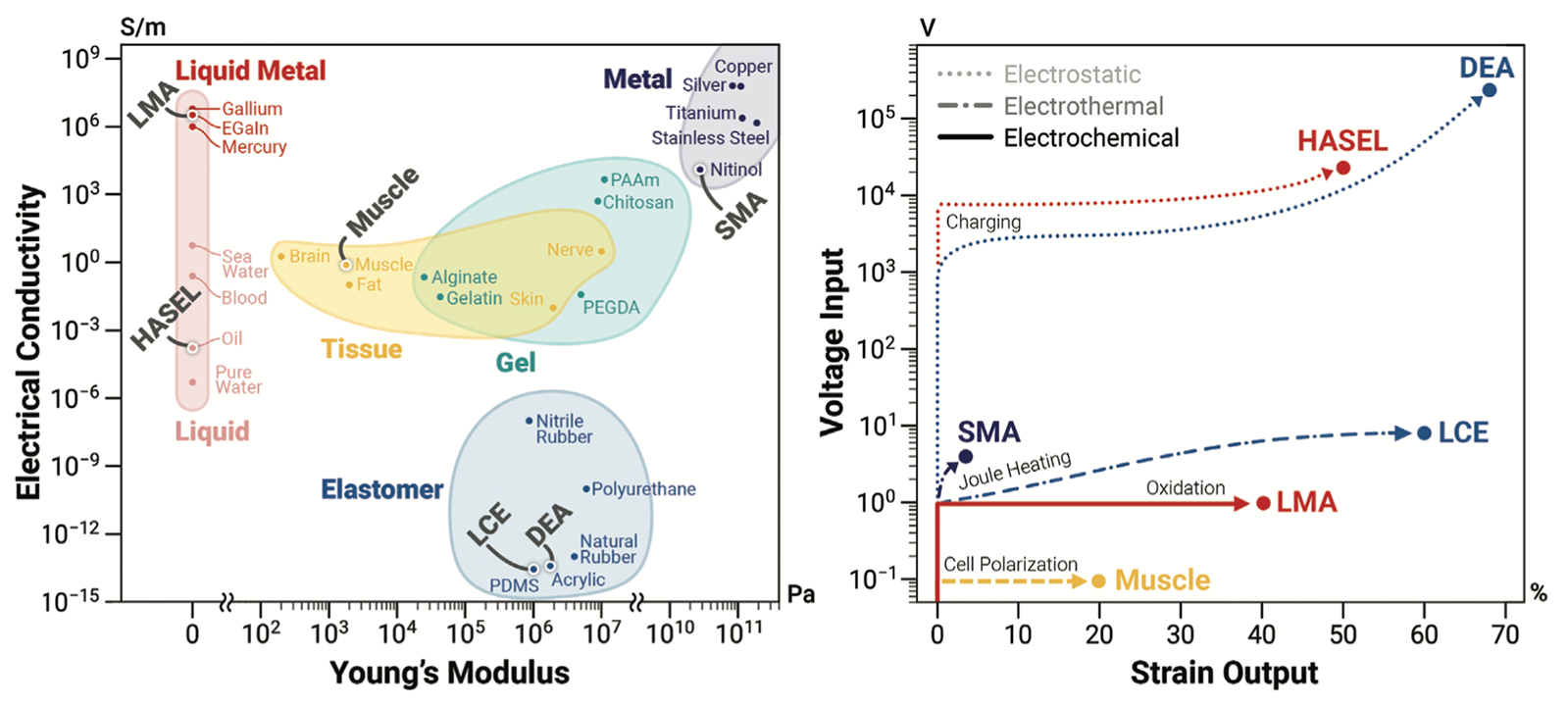

Liao et al. In Preparation.

p

Liao et al. In Preparation.